Integrity, cooperation, development, and win-win

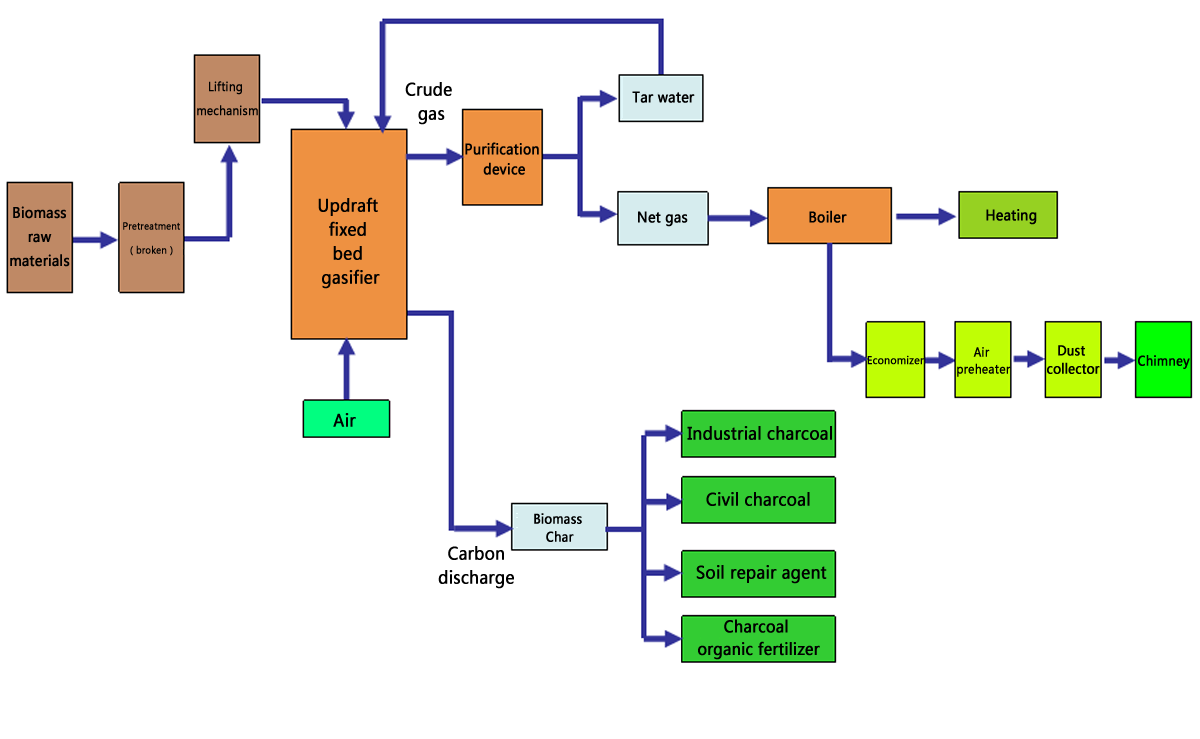

The biomass gasification polygeneration process of this project is as follows:

Biomass gasification heating process flow chart

Biomass raw materials are fed to the furnace top silo through belt conveyor/twisted cage and bucket elevator, and fed from the silo to the gasifier body. The upper part of the furnace top silo is equipped with a feed valve and the lower part is equipped with an outlet discharge valve . Turn off the unloading valve before loading to prevent backflow of gas in the furnace, open the feed valve to feed the biomass raw materials into the furnace top silo; close the feed valve after the feeding is completed, and wait for the unloading valve to be opened in the furnace , Feed the biomass raw materials into the gasifier. The design stock of the furnace top silo meets the feeding demand of the gasifier for continuous operation.

After the biomass feedstock enters the gasification furnace, it passes through the drying zone, pyrolysis zone, reduction zone and oxidation zone from top to bottom, where relevant physical and chemical reactions occur to generate biomass fuel gas, biomass charcoal and biomass liquid, and biomass fuel gas. The boiler is used for combustion and heating, the biomass charcoal is periodically discharged after the bottom of the gasification furnace is cooled and sent to the biomass charcoal field for storage and external sales, and the biomass liquid is returned to the gasification furnace for pyrolysis and gasification.

The air gasification agent is fed in from the air inlet at the bottom of the gasification furnace at a certain flow rate. When passing through the biomass charcoal layer, it exchanges heat and reacts with the high-temperature biomass charcoal. The heated hot gas enters the gasification furnace bottom. The oxidation zone undergoes an oxidation reaction with the hot biomass, and at the same time emits heat, which provides a heat source for the physical and chemical processes of biomass reduction and cracking above the oxidation zone.

The biomass gas produced in the reduction zone and the pyrolysis zone in the gasifier flows upwards, passes through the drying zone, is filtered by the material layer and absorbs heat, is cooled to below 150°C, and is discharged from the gas outlet on the top side of the gasifier. The discharged crude biomass gas passes through a gas purification device to separate the tar, dust and water carried in the gas and return it to the gasifier for pyrolysis and gasification.

The purified biomass gas is transported by the booster fan to the biomass gas boiler for low-nitrogen combustion. After the tar and dust purified by the crude gas are deposited, they are discharged into the tar tank and sent to the gasification furnace by the tar pump for re-pyrolysis and gasification, achieving zero tar discharge and ensuring that the gasification system does not discharge wastewater.